The lever wheel features an axle that’s commonly installed to a shape or live which allows the wheel to rotate freely. That reduces scrubbing when a rope, sequence, or belt works around the pulley. The external side of the pulley could be grooved to greatly help manual the devices, rules, chains or cords preventing them from moving down the pulley during operation.

The programs of a lever wheel may change considerably, and how big the wheel can usually vary on the basis of the purpose for which it has been used. A lever wheel can be used in an automotive motor compartment to support the moment strip or the serpentine gear and the pulley are often applied to power peripheral equipment such as for instance energy steering devices and air conditioners. These pulleys will soon be fairly small. By comparison, an exceedingly large lever wheel works extremely well on a snow raise at a skiing area GEAR COUPLING Manufacturers. That large pulley wheel may help guide the wire on which the seats are secured and it will help to keep appropriate tension on the wire connection.

Production facilities and production services usually make use of pulley wheels as part of a process to guide lift or shift big items. A string or wire could be strung through one or more pulleys and one end of the wire may be attached to the thing that needs to be moved. Introducing pulleys to the procedure will reduce the amount of power needed seriously to lift the thing, nevertheless this may also add friction to the method, therefore making motion more difficult. The proper harmony of pulleys can be used to efficiently carry or shift the objects. A number of these lever techniques are electric to support shift objects quicker and to hold exceedingly heavy objects.

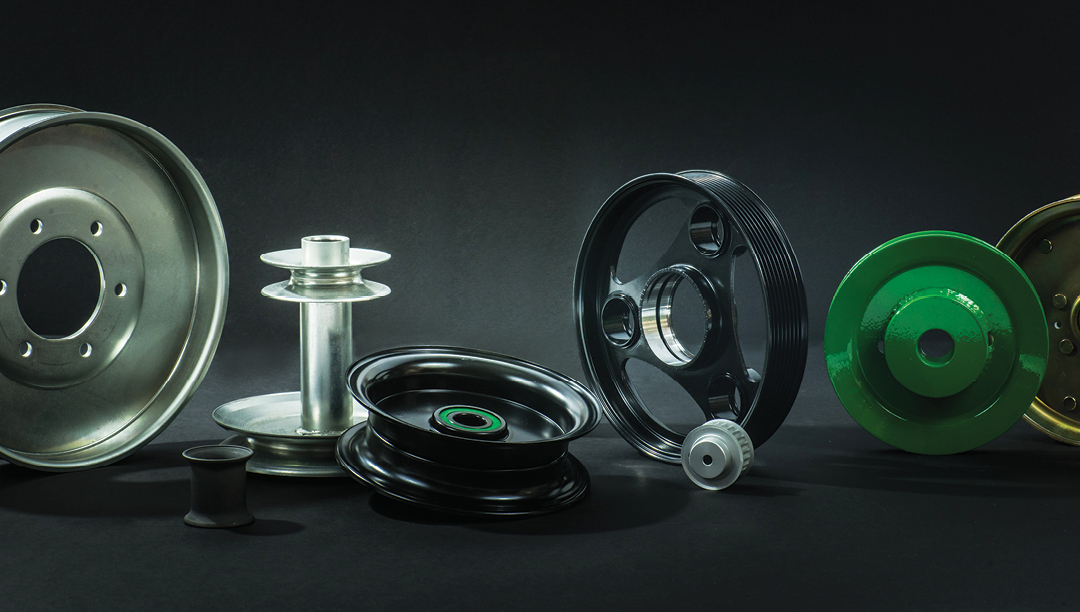

The materials comfortable to create a pulley wheel may possibly change based on the program for which the wheel will be used. For light work programs, a plastic or plastic lever might be adequate, though for weightier duty applications, a tougher more durable substance will soon be necessary. Pulleys utilized by automotive motors like crankshaft lever, moment strip pulleys and underdrive pulleys are generally fabricated from temperature resistant important metals that will not wear out quickly or easily during regular being exposed to high conditions and normal use.

Technical advancement in recent years has smooth just how for machines more powerful and precise than ever before. In the manufacturing industry, electric motors enjoy a crucial role. Through the entire years, their efficiency has been revolutionized numerous of times for maximum performance. In any electric generator readily available for industrial and commercial use, one of the very most common techniques used is the strip and pulley.

This method runs to often lower or increase rate or torque, and for energy indication between shafts, particularly those which are not axially aligned. Those two complement one another wherein the gear balances force whilst the lever controls the speed. Knowledge how they perform can assist you to make the most of their functions in increasing engine efficiency, and at once, support you choose people that are also cost-efficient.